July 14, 2025

Audio overview: Listen & Learn

Running a solar company in 2025 means facing more complexity than ever. From unpredictable supply chains to rising project costs and stricter regulations, staying efficient is no longer optional.

Solar contractors require more sophisticated systems to maintain project momentum and preserve margins in a rapidly evolving renewable energy landscape.

Even as demand for solar energy systems rises, it’s becoming increasingly challenging to maintain lean operations without compromising the solar panel efficiency and quality that customers expect.

7 Proven Ways to Boost Solar Operations Efficiency and Cut Costs in 2025

Whether you're managing five installations a month or fifty, the key to scaling without breaking your margins lies in simplifying your processes. From reducing manual tasks to optimizing project flow, these practical strategies will help your solar business stay lean, competitive, and profitable even when the market gets tough.

Streamlining operations, automating repetitive tasks, and using the right tools can help your team do more with less.

This guide outlines seven proven strategies to help you reduce costs while delivering exceptional results and improving overall efficiency.

Key Takeaways:

- Solar operations efficiency is the key to staying profitable without sacrificing quality or customer satisfaction.

- Centralized solar software reduces errors, boosts team collaboration, and eliminates manual bottlenecks.

- Automating sales-to-installation processes shortens timelines and enhances customer experience.

- Smarter scheduling and inventory management cut costs across your solar operations.

The Rising Cost Pressures Solar Companies Face

As everyone knows, solar companies in 2025 are facing pressure from all sides. Even as the demand for clean, renewable energy grows, so do the challenges that come with maintaining efficient and profitable operations.

From unpredictable pricing on higher efficiency panels to increasing administrative overhead, running a tight ship is more complex than ever. Let’s break down what’s putting pressure on your bottom line.

1. Raw Material Price Fluctuations

The cost of core components, such as solar panels, inverters, batteries, and mounting gear, has become a rollercoaster ride.

Global supply chain issues, increased demand for high-efficiency solar panels, and geopolitical factors all contribute to the situation.

In one month, you plan a project based on today’s price per watt, which influences the anticipated power output. Next, your supplier sends you an updated quote that alters your margins.

For companies relying on solar energy systems and large-scale solar arrays, these pricing swings can cause serious headaches.

And it’s not just about hardware; shipping costs and delays are also part of the equation, especially for premium monocrystalline panels or bifacial solar panels with higher efficiency ratings.

2. Increasing Labor Costs and Talent Shortage

Finding experienced solar installers, licensed electricians, or field technicians who understand the nuances of solar panel efficiency, layout, and advanced panel technology is becoming increasingly challenging.

Labor shortages are driving up wages, and this trend is unlikely to slow down anytime soon. Add to that the cost of training new hires on the job, and you’re looking at longer ramp-up times and a higher risk of installation errors that affect system efficiency.

The reality? It’s taking more money and more time to do the same work you were doing just a couple of years ago.

3. Permit and Interconnection Delays

It’s one thing to sell a solar project. It’s another thing to get it approved. Navigating the permitting and interconnection process can be a tedious and time-consuming ordeal, especially in areas with outdated utility protocols. Some jurisdictions still rely on manual applications or inconsistent permit timelines.

Every day spent waiting on paperwork or utility approvals is a day your solar power system isn’t producing usable electricity. A delay in energy output can affect solar panel efficiency, resulting in delayed revenue for both you and your client.

This bottleneck is one of the quiet killers of solar operations efficiency.

4. Rising Customer Acquisition Costs

Marketing costs are rising across the board. Whether you’re buying solar leads, running paid ad campaigns, or investing in door-to-door canvassing, it’s becoming increasingly expensive to reach a qualified homeowner on the phone.

The solar industry is booming, which means competition is fierce, and customers are more informed and picky than ever. If you’re not using CRM-integrated tools to track your sales process or analyze what’s converting, you’re probably leaving money on the table.

That’s where smarter technology can help reduce solar electricity acquisition costs while maintaining high conversion efficiency.

5. Administrative Inefficiencies and Tech Gaps

You’d be surprised how many solar companies still rely on spreadsheets, disconnected apps, or paper-based workflows to run their business. These gaps don’t just cause delays; they actively affect your team’s solar operations efficiency, particularly when considering thin-film solar panels.

Manually entering customer data across platforms wastes time and invites errors that can lead to costly rework.

And when your sales, design, and install teams aren’t working from the same playbook, things slip through the cracks.

A misplaced contract, a misquoted inverter model, or a forgotten inspection follow-up can impact both energy output and customer trust.

The real challenge isn’t finding areas to cut, it’s knowing how to cut the right ones without breaking your system.

Have a look here for a better understanding. ROI of Solar CRM: A Breakdown of Cost Savings & Revenue Growth.

7 Proven Strategies to Cut Solar Operations Costs Without Sacrificing Quality

1. Strategy #1: Invest in Integrated Solar Software

The first step to improving solar operation efficiency and achieving maximum power output is to replace the patchwork of disconnected tools with an all-in-one solar platform.

Platforms like Sunbase centralize sales, design, operations, and support in one system. The result? Less toggling between apps and more time spent moving projects forward.

Benefits:

- Eliminate double data entry

- Improve accuracy in proposals and estimates

- Enable real-time collaboration between sales, engineering, and field teams

Real-World Savings:

- Fewer errors in system sizing

- Faster turnaround on proposals and approvals

- Less time wasted on admin work

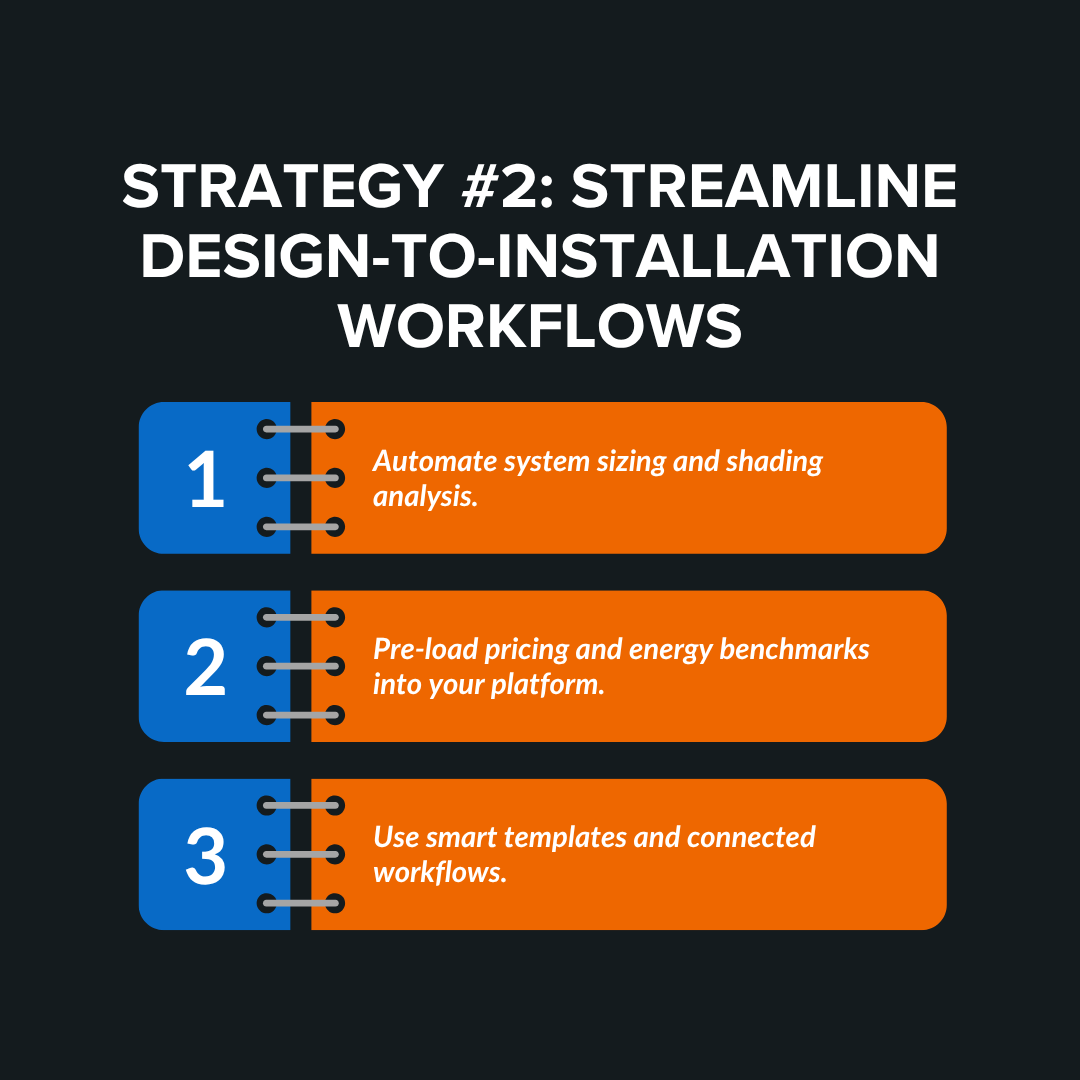

2. Strategy #2: Streamline Design-to-Installation Workflows

The journey from closing a sale to installing panels on the roof may seem simple, but in reality, it's where many solar companies lose time, money, and momentum.

When communication between sales, engineering, and installation teams isn’t airtight, things sometimes fall through the cracks, literally.

Misjudged measurements, outdated pricing, or missing site data can mean redesigns, stalled timelines, and costly rework. In a business built on efficiency, that’s a problem you can’t afford.

Here’s how you can tighten up your design-to-installation handoff:

- Automate system sizing and shading analysis. Instead of manually calculating tilt angles, roof orientation, and solar spectrum exposure, modern tools assess real-world site conditions and optimize designs for maximum power output.

- Pre-load pricing and energy benchmarks into your platform. When your design software already knows your pricing tiers, labor rates, and the expected solar cell efficiency of each module, your sales team can generate detailed quotes that are both accurate and profitable.

- Use smart templates and connected workflows. With templated system specs, proposals, and installation plans ready to go, you avoid reinventing the wheel with every job.

- Data can flow seamlessly from one stage to the next, such as panel specs and solar module details automatically syncing with your installation checklist. That means fewer calls, fewer delays, and way more clarity.

For better understanding, dive into this: How Smart Dashboards Reduce FTE Costs & Improve Decision-Making.

Strategy #3: Optimize Procurement and Inventory

Managing inventory may not be the most exciting aspect of running a solar company, but it can have a significant impact on your margins. Whether you're over-ordering materials that sit unused in the warehouse or scrambling to find components at the last minute, inefficient procurement costs you.

It ties up capital, causes project delays, and frustrates your team. In 2025, smart solar companies are addressing this issue with improved data, more informed planning, and integrated solar operations software.

So, how do you avoid shortages without overspending?

- Track inventory in real time. Stop guessing what’s in your warehouse. Use cloud-based tools that show your inventory levels at a glance, whether it’s polycrystalline panels, mounting hardware, or backup batteries.

- A good solar system management platform will flag low stock, help you avoid duplicate orders, and make sure you’re never caught off guard when it’s time to roll out a crew.

- Forecast material needs based on your project pipeline. If your CRM or project management software integrates with your inventory system, you can automatically see what components will be needed over the next week, month, or quarter.

- This helps you stay ahead of demand, especially as you scale and take on more solar installation projects.

- Partner with regional suppliers. Relying on distant warehouses or overseas shipments can backfire, especially since global supply chains are still reeling from the aftershocks of past disruptions.

- Working with local or regional distributors not only reduces shipping delays but also cuts transportation costs and carbon emissions. That’s a win for your bottom line and your brand.

For businesses, annual savings can be much higher. One medium-sized company reported $28,000 in annual energy savings after solar installation.

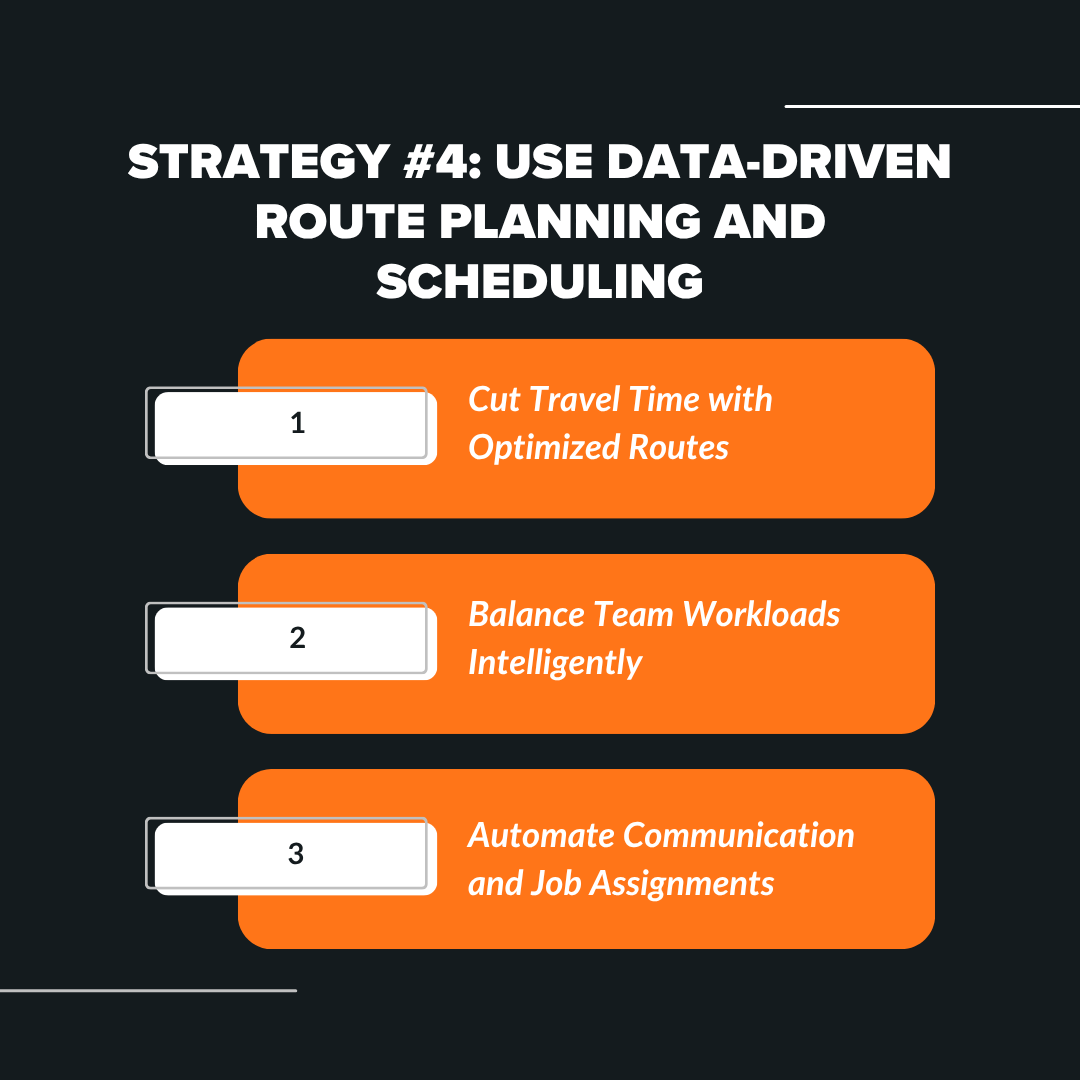

Strategy #4: Use Data-Driven Route Planning and Scheduling

Managing field operations without a smart plan is one of the fastest ways to lose time, money, and momentum in the solar industry.

In 2025, solar companies can't afford to waste fuel or hours due to poor coordination. Route planning and scheduling aren’t just logistics; they directly impact solar operations efficiency, job completion rates, and customer satisfaction.

- Cut Travel Time with Optimized Routes: Using tools that account for traffic patterns and job clustering allows you to reduce mileage between projects.

- Instead of wasting fuel with cross-town drives, installations are grouped by location. This not only lowers your fuel expenses but also reduces unnecessary wear and tear on your vehicle, making every trip count.

- Balance Team Workloads Intelligently: Different projects require different skill sets and time commitments. Whether you’re installing monocrystalline solar panels for a residential home or managing a large-scale solar array using high-efficiency solar panels, smart scheduling assigns the right crew to the right job.

- Automate Communication and Job Assignments: Manual coordination takes time. Automated notifications and mobile access ensure your team knows where they’re going and what’s expected, eliminating the need for endless phone calls and back-and-forth communication.

As solar irradiance data and project complexity increase, companies that adopt smarter scheduling and routing tools are better positioned to maintain system efficiency, enhance solar panel performance, and lower energy bills for their customers.

When your team runs smoother, your entire solar power operation becomes more efficient, leading to faster installations, happier clients, and healthier margins.

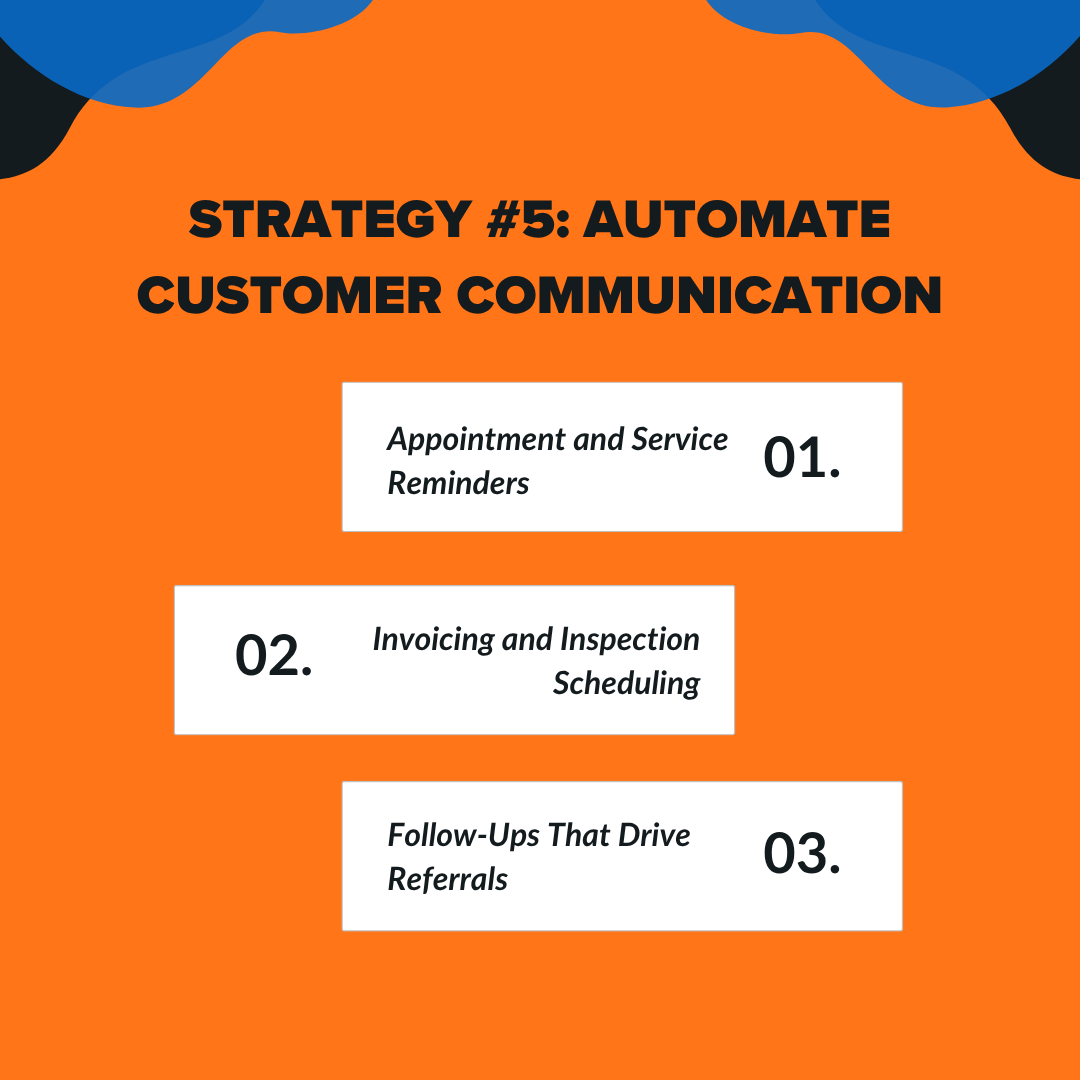

Strategy #5: Automate Customer Communication

When you're trying to grow a solar company, the last thing your team should be doing is chasing paperwork, sending reminder texts, or following up on overdue invoices.

These repetitive tasks, although necessary, consume valuable time that could be spent on installations and project management. That’s where automation steps in, not to replace your customer service but to strengthen it and improve cell efficiency.

1. Appointment and Service Reminders

Sending manual reminders may be effective when managing five projects. But when your team is juggling dozens of solar installations across multiple zip codes, it quickly becomes unmanageable.

By automating appointment confirmations and reminders, your customers stay updated, your field team stays on time, and projects keep moving forward.

2. Invoicing and Inspection Scheduling

Inspection dates and payment deadlines are too important to leave to memory. When integrated with your solar CRM, you can trigger automatic inspection scheduling after a project reaches certain milestones or send digital invoices the moment an installation is complete.

This removes friction from the process, keeping the cash flowing steadily and improving the efficiency of your solar operations while reducing billing delays.

3. Follow-Ups That Drive Referrals

Happy customers are your best marketing tool, but only if you ask for a review at the right time. With a platform like Sunbase, you can set automated follow-ups that thank customers, prompt them for a referral, or invite them to leave an online review, all based on the completion of specific project stages.

It’s a slight nudge with a significant impact on your brand and future pipeline.

By automating communication across the board, you free up your sales and operations teams to focus on what they do best: delivering high-efficiency solar panels, maximizing system efficiency, and helping homeowners understand how solar panels work.

You’ll also be improving your solar panel performance data tracking, customer support consistency, and overall solar energy system output.

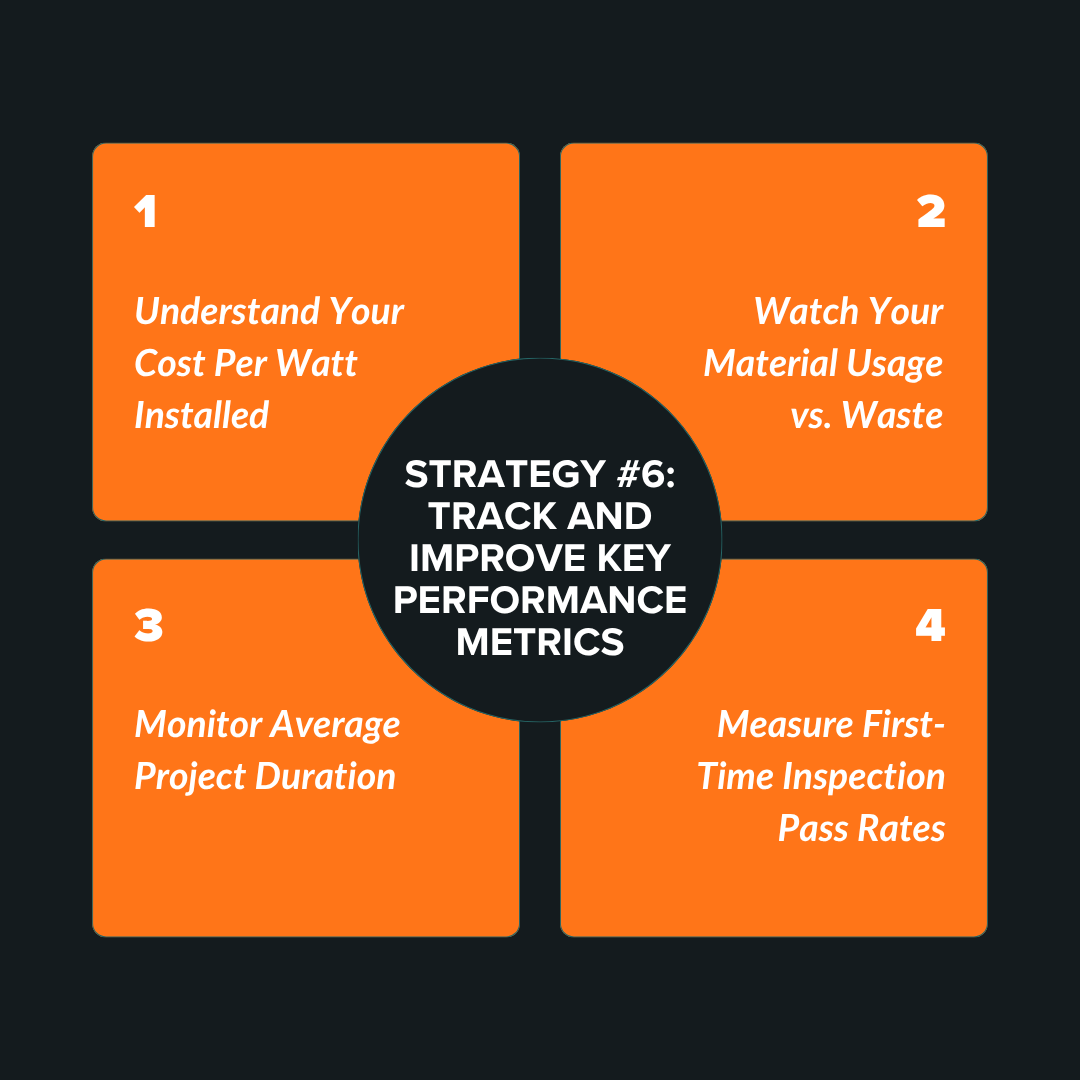

Strategy #6: Track and Improve Key Performance Metrics

Running a solar company without tracking key performance indicators is like flying without a compass. You might get where you're going, but not without unnecessary turbulence or, worse, costly detours.

To truly optimize the efficiency of your solar operations with more efficient panels, you need to measure what matters and use that data to make smarter, faster decisions.

1. Understand Your Cost Per Watt Installed

- This is one of the most important metrics in the solar industry. It tells you how efficiently your team is converting materials, labor, and time into usable electricity for the customer.

- A rising cost per watt may indicate inefficiencies in procurement, design, or scheduling, any of which can subtly impact solar panel efficiency and your bottom line.

2. Monitor Average Project Duration

- From contract signing to final inspection, how long does it take your team to complete a project? Delays can accumulate quickly, especially when dealing with interconnection approvals or unexpected installation issues.

- Tracking average project timelines helps you identify bottlenecks in your solar installation process, providing a clear path to faster and more reliable delivery.

3. Measure First-Time Inspection Pass Rates

- If you're sending crews back to sites to fix issues flagged during inspection, you’re losing time, labor, and money.

- Improving your first-time inspection pass rate directly increases the efficiency of your solar system, both technically and operationally. It also enhances customer satisfaction and reduces unnecessary truck rolls.

4. Watch Your Material Usage vs. Waste

- Solar panels, racking, wiring, everything adds up. Are you consistently ordering too much? Or worse, running short and scrambling mid-project?

- With a good tracking system in place, you can minimize excess energy loss and ensure that your solar modules and materials flow efficiently through each job.

Instead of manually pulling reports from different apps or spreadsheets, everything you need is in one place: cost metrics, labor tracking, solar panel performance, and more.

This kind of visibility gives you a competitive edge by helping you improve everything from panel efficiency to job turnaround times.

To know more about cost-cutting, have a look here: Predictive Analytics in Solar: How Data Science Reduces Operational Costs.

Strategy #7: Leverage Remote Monitoring and Maintenance

1. Maintenance

Rolling out a truck for every system hiccup? That’s one of the fastest ways to drain your budget. Between rising fuel prices and crew availability, routine service calls are no longer as manageable as they once were. That’s where smart, remote monitoring changes the game.

Here’s how it helps you stay efficient and keep clients happy:

2. Catch Performance Drops Early

- Remote monitoring tools detect fluctuations in energy output and solar irradiance the moment they happen. Whether it's a dusty panel, a disconnected wire, or a low-performing solar cell, you’ll receive an alert before a minor issue becomes an expensive repair.

- This kind of insight allows you to take action before your customer even knows there’s a problem.

3. Empower Clients with Transparent Data

- Customers today want more than just clean energy; they want visibility. With self-service portals, homeowners can monitor the daily performance of their solar panels.

- They get to track usable electricity, system efficiency, and overall performance from their phone or laptop. It builds trust and reduces unnecessary support calls.

4. Cut Back on Wasteful Service Visits

- Not every hiccup requires boots on the ground. Remote diagnostics let you know when a physical visit is necessary and when it’s not.

- That means fewer truck rolls, less fuel consumption, and a tighter install-to-service schedule. You can also schedule preventive maintenance based on actual performance, not guesswork.

Upskilling Your Team with Digital Tools

You can have the most efficient solar panels on the market and top-tier solar energy systems, but if your team doesn’t know how to use the tools at their fingertips, you’re leaving serious performance and profit on the table.

That’s why upskilling isn’t just a “nice-to-have” in today’s solar industry; it’s essential. Providing your crew with the knowledge and confidence to work with digital platforms, mobile apps, and performance metrics such as cell temperature and open-circuit voltage can dramatically boost overall system efficiency.

Here’s how consistent training makes a real impact:

1. Fewer Errors in the Field

When installers understand how ambient air temperature or solar irradiance affects power output, they make better on-site decisions. That means fewer callbacks, less rework, and improved solar panel performance from the very start.

2. Higher ROI from Your Software Tools

A powerful solar operations platform only delivers results if your team knows how to utilize it effectively.

Training enhances user confidence and boosts adoption rates, ensuring the software you've invested in drives efficiency improvements throughout your solar installation process.

3. A Team That Wants to Stick Around

People like to feel confident in their work. When employees are allowed to master new digital tools and stay current with trends such as photovoltaic panels, system efficiency, or remote diagnostics, they’re more likely to feel engaged and valued. That leads to higher retention and a stronger, more capable workforce.

Bonus: Where You Shouldn’t Cut Costs

Cutting expenses in solar operations makes sense until it no longer does. There’s a fine line between trimming the fat and cutting into the muscle of your business. Some corners simply aren’t meant to be cut.

Think of it like installing solar panels. You can choose the most efficient solar panels, with high panel efficiency and strong power output, or opt for cheaper, lower-efficiency alternatives, which may lead to performance issues, warranty claims, and customer dissatisfaction in the long run. Not worth it.

Here’s where you should never skimp:

1. Top-Tier Equipment

Don’t compromise on high-efficiency panels, reliable inverters, and high-quality solar modules. Whether you’re installing monocrystalline panels or bifacial solar panels, long-term durability and consistent energy output are non-negotiable.

Going for the lowest bid from solar panel manufacturers might save a little upfront, but it can seriously affect solar panel efficiency and cost you in rework and lost trust.

2. Skilled Labor

Licensed electricians and experienced installers don’t just bring technical know-how; they also bring accountability.

A well-executed solar installation can significantly impact system efficiency and overall customer satisfaction.

From understanding open circuit voltage and power temperature coefficients to navigating tricky rooftops, quality labor delivers long-term value.

3. Customer Experience and Safety

Fast, responsive support, solid warranties, and strict safety standards aren’t optional; they’re expected. Cutting costs on customer service, insurance, or job site safety protocols can backfire fast.

One missed permit, one accident, one ignored callback, and suddenly, you’re facing lawsuits, lost business, or a serious hit to your reputation.

There’s smart saving, and then there’s risky penny-pinching. Protect your brand, your margins, and your peace of mind by knowing when it’s worth spending a little more. Sometimes, the best way to increase solar operations efficiency is simply by refusing to lower your standards.

Conclusion

Cutting costs in solar operations doesn’t mean sacrificing quality or efficiency. By streamlining workflows, optimizing inventory, automating communication, tracking key performance metrics, and leveraging remote monitoring, solar companies can stay lean, productive, and profitable even amid rising material and labor costs.

Investing in the right tools and upskilling your team ensures that high-efficiency panels, skilled labor, and excellent customer experiences remain uncompromised.

With strategic cost management, you can scale your solar business while maintaining long-term performance, client trust, and sustainable growth.

Want to Slash Solar Costs Without Sacrificing Quality with Sunbase?

With real-time data insights, route optimization, and mobile accessibility, Sunbase empowers teams to close more deals, boost productivity, and stay organized—all in one powerful dashboard.

Book your demo now and discover how to scale faster, reduce overhead, and grow smarter in any market.

FAQs

1. How can I reduce costs in my solar operations?

By improving workflows, using centralized software, automating communication, and optimizing scheduling and inventory.

2. What is the solar operations efficiency of efficient solar panels?

It’s the ability to complete solar projects with minimal waste, fewer delays, and maximum productivity.

3. Is investing in solar software worth it?

Yes. The time saved and errors avoided often pay for the software many times over.

I agree to receive marketing messaging from Sunbase at the phone number provided above. I understand data rates will apply, and can reply STOP to OPT OUT.